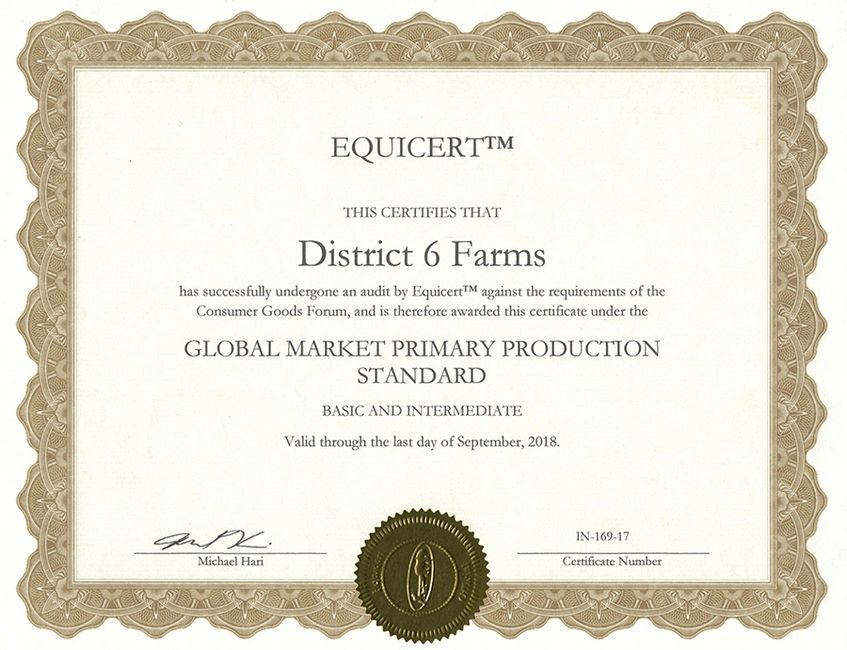

Food Safety

District 6 Farms Food Safety Certificate

AUDITS

District 6 Farms employs independent third-party auditors to verify that GAPs are being followed on every corner of the farm. Audits are performed by certified, independent third-party agencies to ensure adherence to GAPs for food safety set by the FDA. Our Food Safety Program audits are performed in the field, as well as the cooling & packaging facilities to monitor soil, water, fertilizer use, pest control methods, harvest practices, employee hygiene, equipment sanitation, and food safety and security procedures. The results of these audits are reviewed by our Food Safety Manager. If any non-compliance issues are identified, they are immediately addressed and corrective measures put in place.

POLICIES

Adherence to District 6 Farms Food Safety Program policy is a vital component of our employee’s daily tasks. We educate our employees about company policy and enforce strict adherence. Our employees are responsible for adhering to federal, state and local food safety regulations. Each employee is aware that non-compliance carries consequences, up to and including termination of their association with District 6 Farms.

PESTICIDES

In the United States, federal and state laws strictly regulate the use of pesticides. EPA, FDA, state, and county agencies all have regulatory authority governing the safe use of pesticides. District 6 Farms pesticide applicators have spent time in the classroom earning a state-controlled license before they are allowed to apply any pesticides. District 6 Farms proudly partakes in the practice of Integrated Pest Management (IPM). IPM employs a combination of natural and synthetic means to reduce disease and pest pressures. IPM utilizes continual field monitoring and includes the use of beneficial organisms to control damaging pests.

WATER

Water used for irrigation, washing, & sanitation is supplied by a municipal source. Microbial levels in water are monitored throughout the year, ensuring District 6 Farms is adhering to the stringent water quality standards.

FOREIGN DEBRIS

District 6 Farms blackberries are hand-picked and packaged in the field. Harvest crews who pick the berries are thoroughly trained and routinely audited to ensure compliance with GAPs. After being picked, the berries are immediately transported to a packing shed where a team of Quality Control employees look over every clamshell. The packing facility is carefully monitored and audited to ensure compliance.

QUALITY ASSURANCE

District 6 Farms blackberries are grown, harvested and shipped with the highest standards of care possible. We routinely self-audit to ensure that we comply with and exceed national and international food safety rules. Every clamshell of blackberries we produce is inspected for quality and appearance by our highly trained staff to ensure they are safe, fresh, and delicious when they reach our customers. Our blackberries leave the field immediately after being picked. Next, they are inspected by our Quality Control team, and are then immediately placed in the cooler. From this point, our blackberries will not be handled by anyone other than the consumer.

BLACKBERRY TRACEABILITY

District 6 Farms has a barcode-based inventory tracking system in place to identify the field and harvest date of all blackberries. In the rare event of a product quality concern or recall, District 6 Farms can quickly identify what harvest day(s) blackberries are in question, how many blackberries were harvested on those days, when & where those blackberries were shipped, investigate the issue and if necessary, retrieve the blackberries throughout the distribution chain.

Copyright © 2020 District 6 Farms • All Rights Reserved.